Manufacturing is derived from the Latin word manufactus, means made by hand.Manufacturing Engineering is a branch of professional engineering concerned with the understanding and application of Engineering Procedures in Manufacturing Processes and Production Methods.In modern context it involves making products from raw material by using various processes, by making

use of hand tools, machinery or even computers networks, robots, machine tools, and materials-handling equipment.

It is therefore a study of the processes required to make parts and to assemble them in machines. Process Engineering, in its application to engineering industries, shows how the different problems related to development of various machines may be solved by a study of physical, chemical and other laws governing the manufacturing process. The study of manufacturing reveals those parameters which can be most efficiently being influenced to increase production and raise its accuracy.

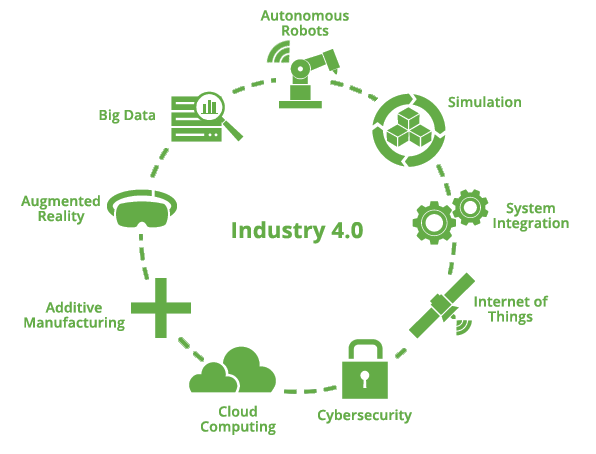

Advance manufacturing engineering involves the following concepts :-

What skills do Manufacturing Engineers need?

- Process planning.

- Process sheets.

- Route sheets.

- Tooling.

- Cutting tools, machine tools (traditional, numerical control (NC), and computerized numerical control (CNC).

- Jigs and Fixtures.

- Dies and Moulds.

- Manufacturing Information Generation.

- CNC part programs.

- Flexible Manufacturing Systems (FMS), Group Technology (GT) and Computer integrated manufacturing (CIM).

- Robot programmers.

2.They work to produce high quality goods efficiently using the most cost-effective methods and with the aim of reducing the impact of production on the environment.

3.Not only does the factory need to produce a product, it also needs to produce it efficiently and be able to meet the demand for the product, and do so at the right cost, quality and delivery timeframe.

- Automate a chemical manufacturing facility through computer integrated technology

- Design circuit board manufacturing processes to reduce costs and improve product quality

- Develop the best assignment of machines and equipment to various manufacturing cells in discrete parts manufacturing

- Develop and implement fabrication processes for nano-/micro-devices

- Identify the most cost-effective material handling and facility layout alternative for an aerospace manufacturing company.

Youre so cool! I dont suppose Ive read anything like this before. So nice to find somebody with some original thoughts on this subject. realy i appreciate you for beginning this up. this amazing site is something that is required on-line, somebody with a bit of originality. valuable problem for bringing something new to the net! best Marketing Assignments wirter

ReplyDeleteThey plan gear and frameworks for building projects. They must sort out how industrial facilities ought to be spread out and the machines that ought to be utilized for supporting effectiveness.Whole Life Cycle Costing

ReplyDeleteHello, I am one of the most impressed people in your article. What you wrote was very helpful to me. Thank you. Actually, I run a site similar to you. If you have time, could you visit my site? Please leave your comments after reading what I wrote. If you do so, I will actively reflect your opinion. I think it will be a great help to run my site. Have a good day.온도테라피

ReplyDelete온도테라피

온도테라피

온도테라피

온도테라피

온도테라피

온도테라피

온도테라피

온도테라피